KVM-GO Production Progress #1

HDMI / VGA Finalized, DP in Final Fit Optimization

Hey everyone 👏 Quick production update to keep things clear and grounded.

KVM-GO is in a healthy and steady stage right now. HDMI and VGA versions are fully locked, and the DP version is in its final mechanical fit optimization so that all variants can share the same enclosure and production flow.

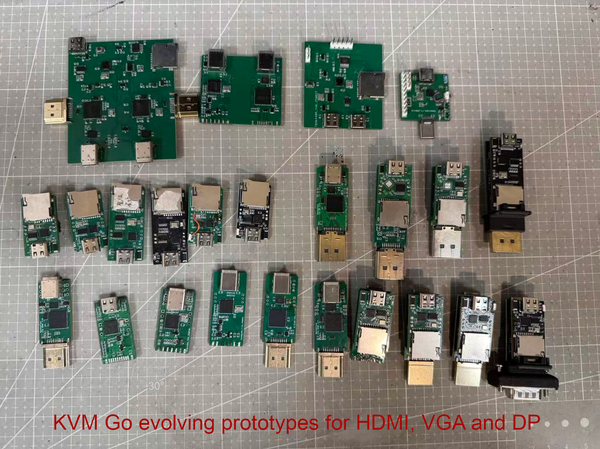

A quick look at KVM-GO’s hardware evolution.

1. Circuit Board Status (DP)

- HDMI + VGA: finalized

- DP: final mechanical optimization (shortening board length to match HDMI/VGA)

This step is purely mechanical / packaging related, not a change in product direction or feature set. The goal is to enable:

- one unified metal enclosure,

- simpler assembly,

- and more consistent, cost-controlled production.

2. Accessories Progress

- Type-C to Type-A black cables: ordered

- Screws: ordered

- Stickers: ordered

- Openterface Toolkit boxes: ordered

- User manual: design in progress

- Product boxes: design in progress

Accessory preparation is moving smoothly and in parallel with hardware validation.

3. Cable & Metal Parts

- HDMI + VGA metal shells: ready

- DP metal shell: pending final DP board length

- Orange USB 3.0 Type-C cables: ready

HDMI & VGA metal shells are ready. The DP shell will follow once the board length is locked for the unified enclosure.

4. Certification & Compliance

We’re preparing materials and test planning for:

- CE

- RoHS

- FCC

- OSHWA submission

Certification testing is now in the preparation stage. We’ll share concrete milestones once lab schedules and results land.

5. Thermal Solution (Validation in Progress)

Because we’re packing high performance into a compact enclosure, thermal validation is being done carefully rather than rushed.

- CNC metal heatsink samples are under test

- Multiple suppliers are being evaluated to compare machining quality and consistency

Thermal tuning through stress testing and material comparisons to ensure long-term stability.

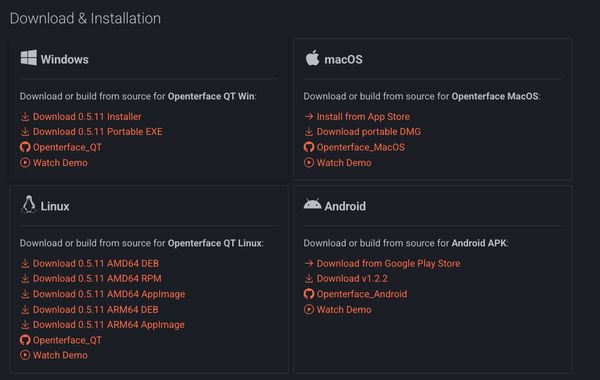

6. Firmware / Software Readiness

Hardware progress continues alongside software validation to keep the out-of-box experience smooth.

- Host app builds are stable; ongoing bug fixes and UX polish continue

- Compatibility testing across macOS / Windows / Linux is ongoing

- iPadOS support: development is being accelerated for an iPad-compatible app

Current host app downloads for Windows, macOS, Linux, and Android.

7. Electronic Components & PCBA

- Electronic components are being purchased and staged

- Mass PCBA will start after compliance confirms the final configuration

This is a normal production workflow and helps avoid rework while keeping manufacturing efficient.

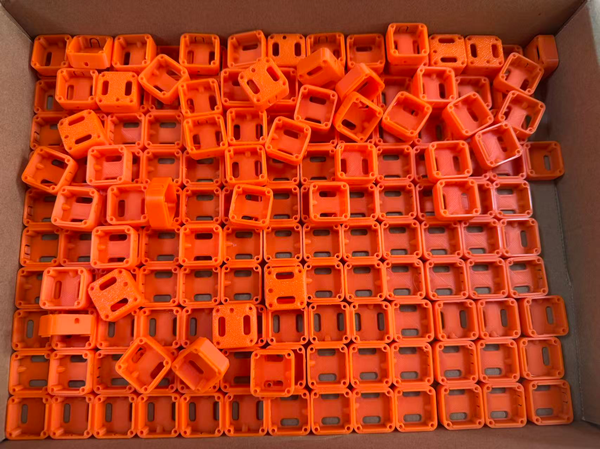

8. Plastic Parts

- Orange cover: 3D printing profile tuning in progress

- Nylon black cover: ordered

Orange cover printing in progress while we tune for consistency and surface quality.

What’s Next

In the next update, we’ll share:

- DP final board length confirmation and enclosure fit check

- Certification progress and lab scheduling updates

- Final thermal solution decision (heatsink + interface material)

Thanks again for backing a small team building practical, open hardware. We’ll keep updates frequent, honest, and grounded in real progress.

Openterface Team | TechxArtisan